Dispensing in electronics production

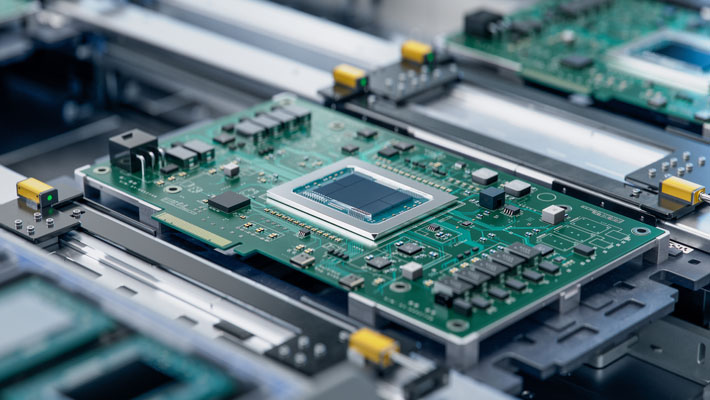

In electronics production, VIEWEG dispensing systems apply the smallest quantities of adhesives, pastes, fluxes, paints, greases or other fluids precisely, reliably and reproducibly. This allows individual dispensing processes to be automated and accelerated.

Example jet process

Manufacturers of placement systems integrate our compact adhesive dispensers into their machines. This saves the operator an additional gluing station. In SMD assembly, the VIEWEG jet valves shoot the dispensing medium directly onto the circuit board. As each drop has exactly the same shape, a vision system can automatically check the application and thus ensure quality.

The non-contact jet process is particularly useful for "underfill" applications. In contrast to classic dispensing with a dispensing needle, height differences of the components play a subordinate role, as the fluid is applied from a safe distance and damage to the component can therefore be completely ruled out.

Sustainability

VIEWEG dispensing valves are designed to be so robust that they function reliably even in harsh industrial environments and are easy to maintain. When using abrasive media, the modular design pays off because the customer can replace all fluid-carrying components and wear parts themselves.

Service

VIEWEG not only supplies you with a catalog product, we also support you in the process of development from the preliminary development to the finished system. Benefit from our 40 years of experience in the field of dispensing technology and let our sales engineers and application experts help and advise you.

Efficent

In a large number of applications, the right choice of dispensing system or the right automation has increased production speed by up to 70 percent with greater dispensing accuracy. Let our dosing experts advise you. We are also happy to answer questions on how dispensing processes can be automated efficiently.

Dispensing applications for

Assembly of SMD components

Assembly of SMD components

Conformal coating

Conformal coating

Potting of bond wires and housings

Potting of bond wires and housings

Selective coating

Selective coating

Glob-top process

Glob-top process

Bonding of passive electronic components

Bonding of passive electronic components

Underfill process

Underfill process

Optical bonding

Optical bonding

Dam-and-fill process

Dam-and-fill process

Potting of transformers

Potting of transformers

Coating for insulation purposes

Coating for insulation purposes

Potting of connectors

Potting of connectors

Masking for galvanic processes

Masking for galvanic processes

Dispensing solder pastes

Dispensing solder pastes

Processing of thermally conductive pastes

Processing of thermally conductive pastes

Dispensing of resistance pastes

Dispensing of resistance pastes

Processing electrically conductive materials, e.g. silver conductive adhesives

Processing electrically conductive materials, e.g. silver conductive adhesives

Dispensing of conductive tracks

Dispensing of conductive tracks

Marking of good/bad parts

Marking of good/bad parts